Discover the mechanics and benefits of Lay Flat binding. From Otabind to seamless photobooks, learn why this 180 degree opening technique is revolutionizing user experience in premium printing.

|

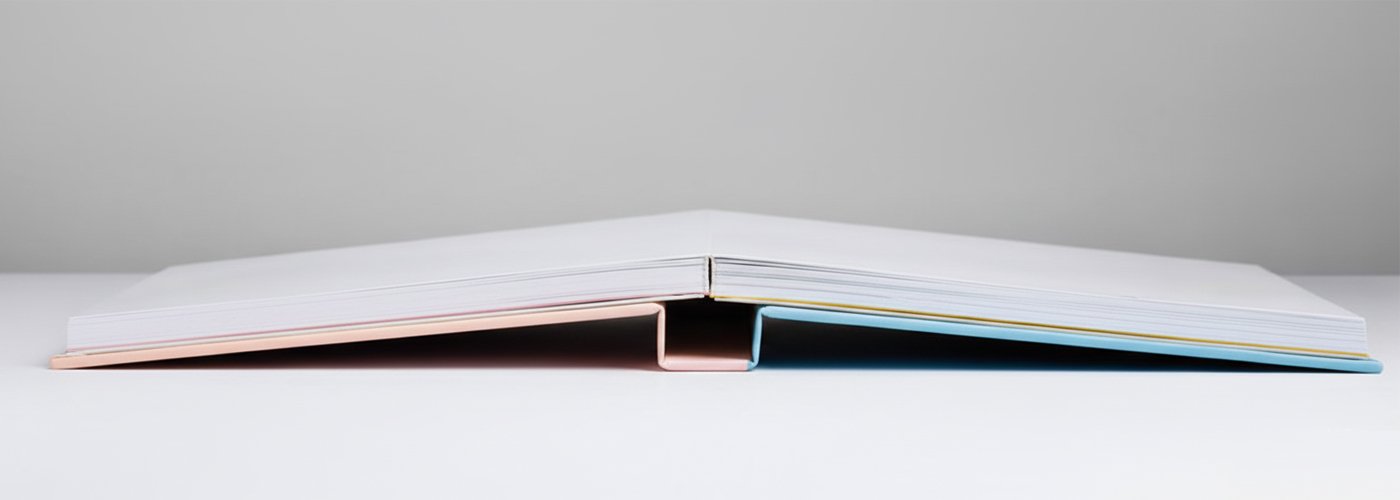

Discover the mechanics and benefits of Lay-Flat binding. From Otabind to seamless photobooks, learn why this 180-degree opening technique is revolutionizing user experience in premium printing. Redefining the Reading Experience: What is Lay-Flat Binding? In the world of professional printing and book manufacturing, few finishing techniques have sparked as much interest and demand as Lay-Flat binding. Traditionally, the standard "perfect binding" method—while cost-effective—came with a significant functional flaw: the book's tendency to snap shut or the need for the reader to break the spine to keep it open. Lay-Flat binding is the premium engineering solution to this age-old problem. As the name implies, this advanced bookbinding method allows a book to open a full 180 degrees and remain completely flat on a surface without any resistance. By utilizing specialized adhesives (such as Polyurethane Reactive or PUR glue) or innovative construction techniques like "floating spines," the text block is liberated from the cover. This ensures that whether the book is resting on a kitchen counter, a music stand, or a boardroom table, it remains open, offering an uninterrupted, hands-free reading experience. For publishers and businesses aiming to prioritize user experience (UX), transitioning from standard perfect binding to Lay-Flat binding is not merely an aesthetic choice; it is a functional upgrade that signals quality, durability, and attention to detail.

The Mechanics of Perfection: How Lay-Flat Technologies Work Understanding the superiority of Lay-Flat binding requires looking "under the hood" at how these books are constructed compared to their traditional counterparts. While there are several variations, such as the Otabind method (which uses a flexible lining to prevent the cover from sticking to the spine glue), the most premium iteration—often championing the photobook market—relies on a unique folding and gluing process. In this seamless approach, the process begins with single-sided printed pages. These sheets are folded in half with the print facing inward, and then the blank reverse sides are glued to the opposing blank sides of the next spread in the sequence. This continues until a complete block is formed. This specific technique yields three distinct technical advantages over perfect binding. First, it eliminates the "gutter"—the area in the center of the book where content usually gets lost in the fold. Second, because pages are essentially glued back-to-back, the resulting leaves are double-thick, providing a substantial, luxurious weight that resists tearing and curling. Third, the mechanics of the bind allow the spine to flex freely, preventing the unsightly cracking and structural damage that frequently plagues standard paperbacks after repeated use.

Unlocking Creative Potential: The Power of Seamless Spreads For graphic designers, photographers, and luxury brands, the most compelling argument for Lay-Flat binding is the liberation of the "spread" as a single, cohesive canvas. In standard binding, designers must account for a safe margin in the center of the book, often breaking images or text to ensure legibility. Lay-Flat binding removes these boundaries entirely. Because the book opens flush across the center fold, interrupted only by a microscopic fold line, panoramic images can flow seamlessly from the left page to the right page without visual disruption. This capability is critical for high-impact visual content. Imagine a landscape photography portfolio where a horizon line stretches unbroken across 24 inches, or a corporate catalog showcasing a complex architectural blueprint that requires the full width of the open book to be understood. This "seamless spread" capability transforms a book from a simple conveyor of information into an immersive visual experience. The aesthetic impact is matched by the physical feel; the double-thick pages mentioned earlier turn every page turn into a deliberate, tactile interaction, subconsciously reinforcing the value of the content printed upon them.

Strategic Applications: When to Choose Lay-Flat Binding While Lay-Flat binding is a premium feature, specific use cases benefit disproportionately from its implementation. The most obvious candidates are cookbooks and recipe books. A chef with flour-dusted hands cannot constantly hold a book open; they need a recipe to lie flat on the counter for quick reference. Similarly, instruction manuals, workbooks, and sheet music demand a hands-free experience to be functional. If a user has to fight the book to keep their place, the product has failed its primary purpose. Beyond utility, the format is the gold standard for photo albums and coffee table books, where the preservation of photographic integrity across the spread is paramount. Furthermore, in the corporate sector, high-end catalogs and real estate brochures utilize Lay-Flat binding to project an image of luxury and stability. If your aim is to provide customers with a product that is not only beautiful but also practically superior—avoiding the frustration of snapping pages—Lay-Flat is the only logical configuration. It bridges the gap between the durability of a hardcover and the flexibility of a high-end journal.

The Future of Finishing: Accessibility and Production Evolution Historically, the adoption of Lay-Flat binding was hindered by two factors: high production costs and slow turnaround times. The specialized machinery required to produce true Lay-Flat books—capable of precise folding and gluing—represents a significant capital investment, often exceeding £100,000 for top-tier equipment. Additionally, the process of gluing pages together was viewed as complex and time-consuming compared to the rapid-fire speed of standard perfect binding lines. However, the industry is undergoing a shift. As technology advances, production capacity has increased, and lead times have plummeted. Modern production workflows are now capable of matching the 48-hour turnaround times previously reserved for standard binding, making Lay-Flat accessible for tighter deadlines and broader budgets. For print service providers and machine manufacturers, championing this technology is no longer a niche endeavor but a necessity for staying competitive. By offering enhanced durability, superior design capabilities (like panoramic spreads), and unmatched user friendliness, Lay-Flat binding has evolved from a luxury novelty into the definitive standard for high-quality printed media. |

| Tag:lay flat binding,layflat bind,photo book,book binding |

Please Leave Your Messenger Here!

We will do our best to make your business prosperous!