Discover the HX6000 PRO High-Speed Automatic Book Block Preparation Line. Featuring 70 cycles/min speed, 30T pre-pressing, and precise end sheet lining for superior hardcover binding

|

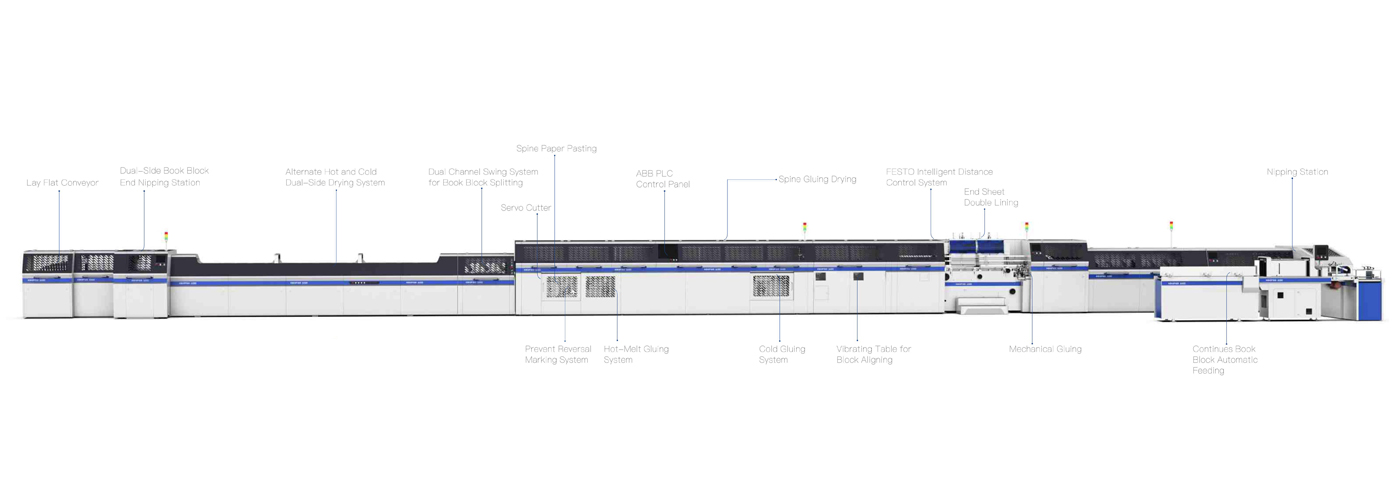

The HX6000 PRO is a high-speed, fully automatic book block preparation line designed to process thread-sewn or loose-gathered book blocks for hardcover binding. Capable of running at speeds of up to 70 cycles per minute, this machine automates critical processes such as pre-pressing, end sheet lining, back gluing, and spine paper pasting, making it a vital component for high-efficiency printing workshops.

The following is a step-by-step overview of the machine's workflow and its key components: 1. Feeding and Pre-Pressing The process begins with the Book Block Infeed Conveyor. An operator places book blocks into a stack, where they are automatically split and fed individually into the system via a cycled infeed conveyor. Upon entering the line, the blocks undergo Three Times 30T Mechanical Pre-Pressing. Unlike hydraulic or pneumatic presses, this mechanical system applies 30 tons of pressure to effectively exhaust air from within the blocks and compact them, ensuring high-quality binding for thick books.

2. Alignment and End Sheet Lining After pre-pressing, the blocks move to a Vibrating Table for precise alignment (neating). They then enter the Twin End Sheet Lining Station. This station glues end sheets to both sides of the book block simultaneously. A unique feature here is the Thread Head Sucking Function, which prevents threads from getting into the back of the blocks, thereby reducing defective products.

3. Intelligent Control and Detection To ensure smooth high-speed operation, the machine utilizes a FESTO Intelligent Distance Control System (also described as a servo-driven block gap control). This patented technology ensures book blocks of different sizes enter the gluing stations at equidistant intervals, optimizing production speed and saving spine paper. Concurrently, a Book Block Thickness Detection system acts as a misfeed and double-sheet control, checking for missing or replicated signatures before gluing begins.

4. Gluing and Drying Systems The core binding process involves a multi-stage gluing and drying sequence: • Cold Gluing: The blocks first pass through an Immersing Cold Gluing Unit, which includes an integrated flushing and cleaning system.

• Initial Drying: This is followed by an IR (Infrared) and Hot Air Drying section to dry the back of the blocks.

• Hot-Melt Gluing (Optional): For high-quality projects like bibles or dictionaries, the line can be equipped with a Hot-Melt Gluing System to further solidify the book back.

• Spine Paper Pasting: The machine then applies spine paper (back stripping). This station features a Prevent Reversal Marking System to ensure accuracy.

5. Splitting and Post-Pressing Once gluing and lining are complete, the book blocks reach a Dual Channel Swing System. A servo-controlled swing head splits the single stream of blocks into two separate channels.

The blocks then travel through a Dual Channel Drying section for deceleration and final drying, ensuring they are ready for subsequent cutting processes. Finally, the process concludes at the Dual Channel End Press (Post-pressing station). This system uses a servo-driven pushing function to increase compacting time, ensuring the finished book blocks are perfectly shaped and consolidated. |

| Tag:HX6000 PRO,Book Block Preparation Line,Automatic Back Gluing Machine,End Sheet Lining Machine,Hardcover Book Binding Machinery |

Please Leave Your Messenger Here!

We will do our best to make your business prosperous!