Ready to upgrade your hardcover production? Contact HXCP today to learn how the HX Classic 680 Automatic High Speed Hardcover Book Production Linecan optimize your bindery workflow.

|

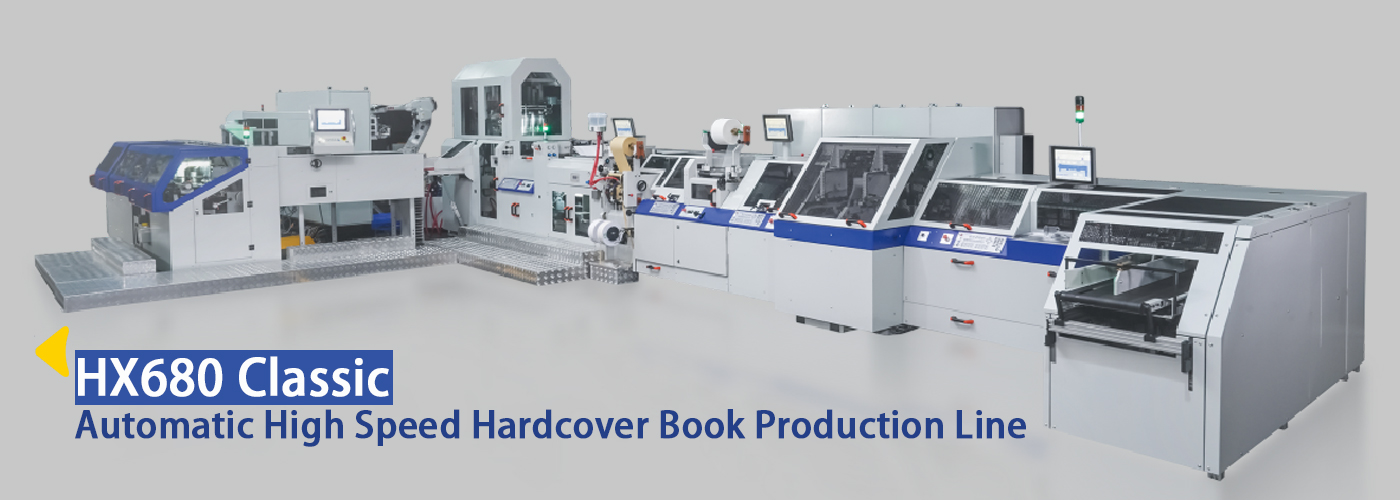

In the competitive world of industrial bookbinding, efficiency, precision, and stability are paramount. Introducing the HX680 Classic Automatic High Speed Hardcover Book Production Line—China's first and only high-speed solution designed to meet and exceed international standards. Engineered by HXCP (Haoxin Precision Machinery), this machine represents the peak of intelligent post-press technology, offering a robust alternative to traditional European models like the Kolbus BF527 and Muller Martini lines. Whether you are producing textbooks, bibles, or premium trade books, the HX680 Classic Automatic High Speed Hardcover Book Production Line delivers consistent quality at speeds of up to 60 cycles per minute.

Executive Overview The HX680 Classic Automatic High Speed Hardcover Book Production Line is a fully automated casing-in system designed for the industrial production of hardcover books. It integrates complex binding processes—from block rounding and backing to spine gluing and casing-in—into a single, streamlined workflow. Built with a heavy-duty ductile iron frame rather than standard steel plates, the machine offers superior shock absorption and stability, ensuring durability even during 24/7 high-speed operation. Its design philosophy emphasizes "mechanical transmission consistency," ensuring that rounding, gauzing, and casing-in actions remain perfectly synchronized. The Production Workflow The HX Classic 680 Automatic High Speed Hardcover Book Production Line mimics the proven reliability of the Kolbus BF527, utilizing a linear, logical workflow that guarantees the highest quality for finished books. The process includes: 1. Infeed & Star Feeder: The book block is fed into the system via the front edge notch and placed onto the line by a precise star feeder. 2. Rounding & Backing: The block passes through a preheater to the Rounding Station, where rollers shape the spine. It then moves to the Backing Station, where backing jaws and a forming iron create the mushroom shape (joint) required for high-quality hardcovers. 3. Spine Preparation: During timed transport, the spine undergoes hot melt gluing, gauzing, and lining. 4. Headbanding: Head and tail bands are applied with precision. 5. Rub-Down Station: A Teflon band with an integrated foam rubber element presses the lining material firmly onto the spine, adapted perfectly to the book's radius. 6. Case Forming: Hardcover cases are fed continuously, heated, and rounded at the spine to match the book block. 7. Casing-In: The book block is pushed onto a Splitter Sword, and transport wings guide it into the aligned case. The splitter sword design allows for the handling of diverse paper types, from thin 28g bible paper to thick 250g cardstock, preventing wrinkling or damage. 8. Pressing: The block and case are pressed together in the book clamp system to ensure a permanent bond before delivery.

Key Features For print shops looking to upgrade their bindery, the HX680 Classic Automatic High Speed Hardcover Book Production Line offers distinct advantages over competitors (such as the Muller Martini 60D): • Intelligent Control System: Equipped with an ABB Servo System and a user-friendly HMI touch-screen panel. Unlike complex code-based systems, the HX680 uses visual, intuitive controls for faster setup and troubleshooting. • Enhanced Stability: The machine utilizes 7 clamp plates (compared to the standard 6 found in competitor models like the MM 60D). This allows the machine to run smoother at high speeds (60 books/min) without sacrificing stability. • Superior Rounding & Joint Formation: Features an internal cam structure for high-pressure rounding and a 20T hydraulic pressure system for the joint area, ensuring sharp, consistent spine formation even on thick books. • Scratch-Free Case Feeding: The continuous case feeder uses a rotary nozzle design (pre-spin) to prevent scratching delicate cover materials, a common issue in belt-driven systems. • Versatility: The line is capable of handling a vast range of sizes, from a minimum block of 100x100mm to a maximum of 280x375mm, making it ideal for everything from pocket dictionaries to large-format art books. Technical Specifications • Maximum Mechanical Speed: 60 cycles/minute • Book Block Size (Max): 280 × 375 × 80 mm • Book Block Size (Min): 100 × 100 × 2 mm • Machine Weight: 16,350 kg • Power Requirement: 57.6 kW (for 7 stations) • Dimensions: Approx. 12.9m (Length) × 2.6m (Width) × 2.7m (Height)

Application Scenarios The HX680 Classic Automatic High Speed Hardcover Book Production Line is the ideal solution for: • Commercial Printing Houses: Handling high-volume orders with tight deadlines. • Education Publishing: Producing durable textbooks and reference materials. • Religious Publishing: Specifically engineered to handle thin paper (e.g., Bibles) without tearing or wrinkling. • Stationery Manufacturing: High-quality notebooks and diaries with rounded corners and elastic bands.

Why Choose HX680 Classic Investing in the HX680 Classic Automatic High Speed Hardcover Book Production Line means choosing cost-effectiveness without compromising on European-standard quality. While comparable imported machines face long delivery lead times and expensive spare parts, HXCP offers robust local support, readily available parts, and a design that has been market-proven to rival the efficiency of the Kolbus BF527.

Ready to upgrade your hardcover production? Contact HXCP today to learn how the HX680 Classic Automatic High Speed Hardcover Book Production Line can optimize your bindery workflow. |

| Tag:casing-in machine,hardcover book,Hardcover Book Production Line,Kolbus BF527 |

Please Leave Your Messenger Here!

We will do our best to make your business prosperous!